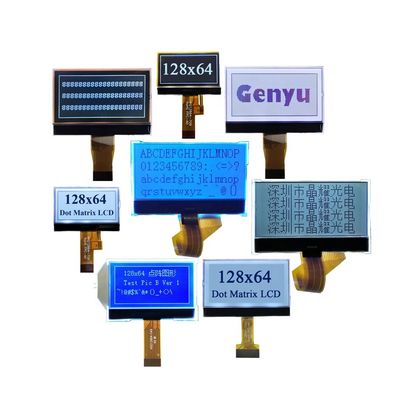

Quality Control

Genyu's quality control test equlpment.

At Genyu, quality control (QC) is the backbone of our manufacturing process, ensuring that every LCD panel meets the highest standards for performance, reliability, and durability. With two decades of expertise, we have developed a comprehensive QC system that spans every stage of production.

Incoming Material Inspection (IMI)

• Material Verification: All raw materials, such as glass substrates, liquid crystals, polarizers, and electronic components, are inspected upon arrival to ensure they meet strict specifications.

• Testing Methods: Advanced testing equipment is used to check for dimensional accuracy, purity, and structural integrity.

• Visual Inspection: Each LCD panel is examined for visible defects such as scratches, alignment issues, or pixel irregularities.

Performance Testing:

• Brightness and Contrast: Ensures optimal visual performance.

• Color Accuracy: Evaluates color fidelity and consistency.

• Response Time: Measures how quickly the display reacts to changes.

• Temperature Resistance: Tests the product’s functionality under various environmental conditions.

Reliability Testing:

• Vibration and Drop Tests: Ensures durability during transportation and usage.

• Lifetime Testing: Simulates prolonged use to assess longevity.

Genyu Certificate

Continuous Monitoring: Each step of the production process is monitored for adherence to quality standards.

Testing and Inspection: We conduct rigorous testing for every batch, including functionality, durability, and compliance with industry standards.

ISO Standards: Genyu complies with ISO certifications and maintains a culture of continuous improvement.

RoHS Standards: All products are RoHS compliant.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!